When building or designing a new feed mill, there are plenty of different factors to consider. No two facilities are exactly alike. You’ll need to adjust your plans based on the size of your facility, what you’re trying to achieve, and what kinds of animals you’re looking to raise, all the while maintaining the health and safety of your employees.

Keep these considerations in mind when designing a feed mill for your business:

- What is the product or recipe that you’re looking to process?

You’ll need to consider the incoming product when creating your feed mill. Different products like flour, grain, and rice require different milling techniques. For example, roller mills cannot process flour, while hammer mills can. If you’re combining different materials and products into the same feed mill, you’ll need a mill that’s designed for universal applications.

- What size granulation do you need?

Different animals require different sizes of feed based on their digestive systems. Cows require larger, coarser particles that are high in fiber, while pigs require finer particles of a certain size. Feeding your animals the wrong sized particles will lower your feed conversion rates. Consider the needs of your animals before investing in a feed mill.

- What capacity is needed?

You also need to consider how much feed you’ll need to produce at any given time. Some feed mills come with strict throughput limits, so you may want to consider choosing a different model if you plan on producing large quantities of feed. Some models are prone to excess heat, friction, and costly repairs when operating at high volumes, so make sure your new system can handle the intake to maximize your milling efficiency.

- Are there any limitations? Space limitations? Electrical limitations?

You should also know the limitations of your facility before investing in a feed mill, including the size of the space, how you plan on having your employees move throughout the facility, as well as any electrical limitations. Your employees should be able to move throughout the space freely without running into equipment or potential hazards. You’ll also need to position your equipment for optimal efficiency, so your employees can complete their work in less time.

- Is this a new product, something that no one has milled before?

If not, what type of testing is needed? If you’re creating a new product or working with a new recipe, you’ll need to test the product beforehand to make sure it’s safe for your equipment. Additional steps may be required before putting the material through the machine.

- Mill Safety

The health and safety of your employees should always be a top concern. Some feed mills can generate excess heat and friction that may put your employees at risk. Some machines are prone to spontaneous combustion, so you may need to invest in explosion protection, as well.

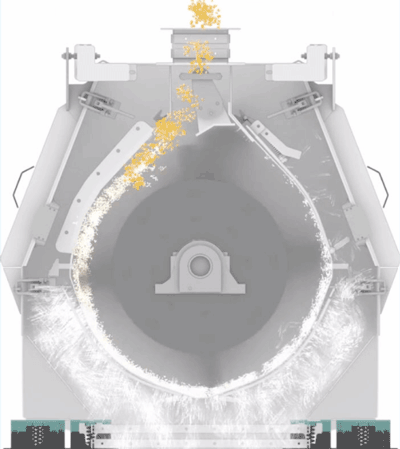

Once you’ve done your research, you can start planning out the details of your new facility. Consider partnering with an experienced feed mill design and construction firm, so you don’t have to make all these decisions on your own. The professionals at Halverson Company can help you design and construct the perfect mill for your business. We invest in the latest grain and feed mill technology, including Buhler’s Multi-Impact Hammer Mill, to help our customers accomplish their goals. The Multi-Impact Hammer Mill produces less heat and friction than other models, so you can process more feed without endangering your employees or paying for costly repairs.

Keep these ideas in mind to make the most of your new facility.