Over 100 Years of Design/Build

We build lasting value in

every project

Since 1914, Halverson Company has been the safe and trusted choice when businesses must tackle large scale construction or maintenance projects. Some of the world’s leading milling, processing and grain handling companies have come to rely on Halverson for its superior ideas, design, project management and safety record.

Industries We Serve

Halverson is a full service company

Our Equipment Providers

Industry Resources

COVID-19 Checklist for Animal Food Operations

In the wake of the COVID-19 pandemic, the U.S. Food and Drug Administration (FDA) and Occupational Safety and Health Administration (OSHA) have released new safety guidelines for feed mills, including human and animal food operations. Feed mills are considered...

Design Tips for New Feed Mills

There are many factors to consider when designing a new feed mill. Small changes can yield major savings down the line. It’s important to focus on construction safety, energy efficiency, and the maintenance process when creating the layout of the facility. Companies...

Understanding Feed Mill Formulas

Every feed mill must create a series of formulas or recipes for their products, using a series of mathematical equations. This ensures the recipe can be replicated consistently. It also allows the mill to scale these recipes as needed without altering the nutritional...

Reduce Feed Waste

Food waste can be a major expense in the feed processing industry. Poor storage and grain handling can lead to a range of problems, including contamination, mold, and mildew. There are several ways to reduce feed waste throughout the production process. Use these tips...

Preventing Grain Entrapment

Handling and processing grain materials come with plenty of risks, particularly those related to entrapment. Large amounts of grain can suffocate workers in a matter of seconds. That’s why feed mill managers need to ensure their employees are adhering to the latest...

Grain Conditions & Safety

The condition of your grain and agricultural materials can be a major hazard to your employees. In addition to using caution when handling and processing these materials, you need to make sure your facility has the right materials to store your grain properly for the...

Conveyor Systems and Feed Contamination

Reducing cross-contamination often means changing how your grain handling facility processes and transports your animal feed. If your ingredients or materials leave behind residue, you will need to clean the equipment before loading on another batch of feed. Conveyor...

National Farm Safety & Health Week 2020

The National Farm Safety & Health Week 2020 is a six-day event centered on farmers and agricultural producers with the aim of improving safety for all types of professionals. This year’s festival is set for September 20- 26, with the theme “Every Farmer Counts.” The...

Feed Traceability and COVID-19

The Food and Drug Administration (FDA) was planning to release new food safety and traceability guidelines in March 2020, but the new rules will incorporate additional safety practices to prevent the spread of COVID-19 and other infectious diseases. While the...

Feed Mill & Safety

Safety should be a top priority when managing or operating a feed mill. From the feed mill construction to daily operations, you need to protect your workers from slips, falls, and other types of injuries on the job, while making sure that your feed is safe for...

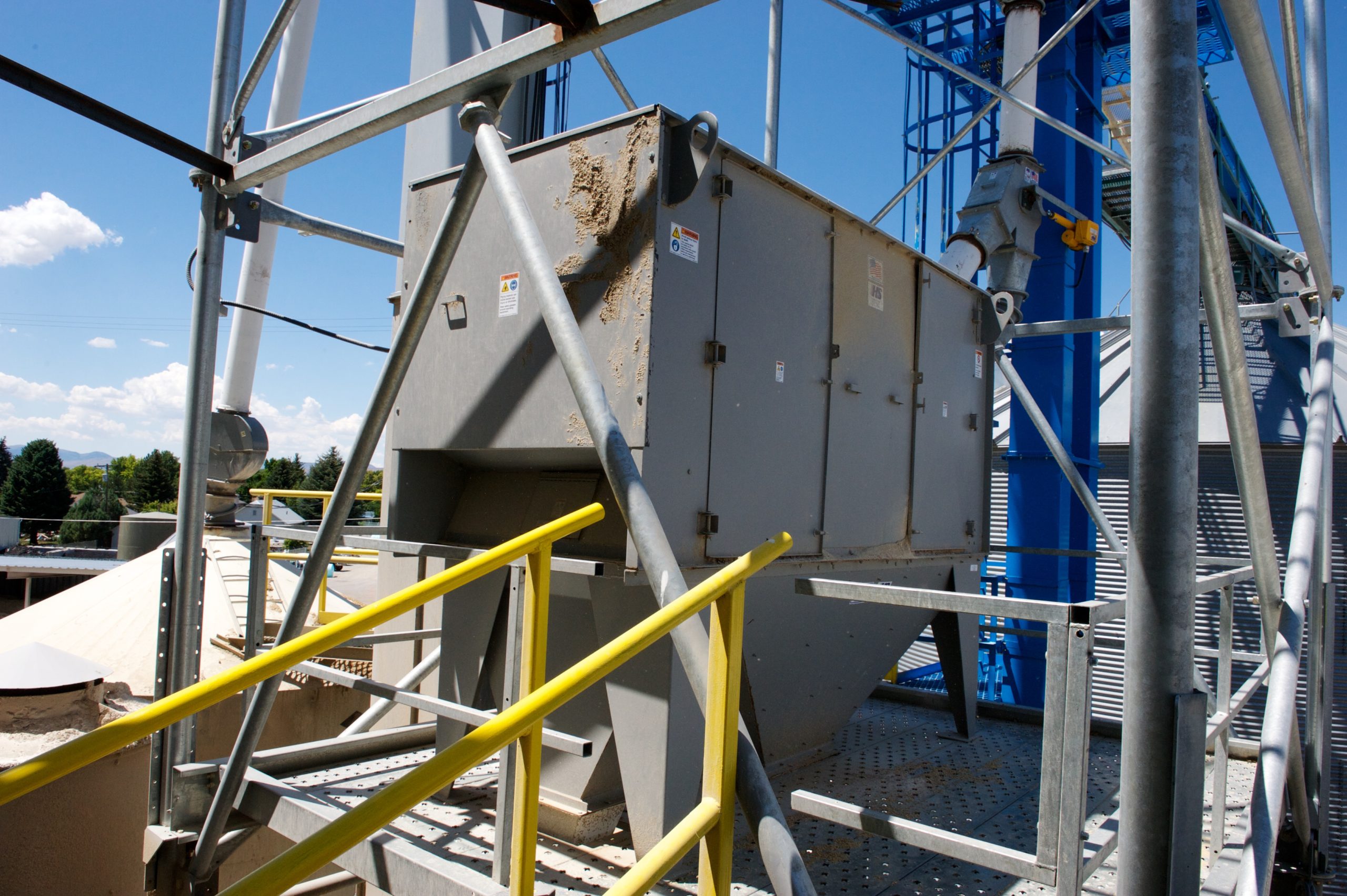

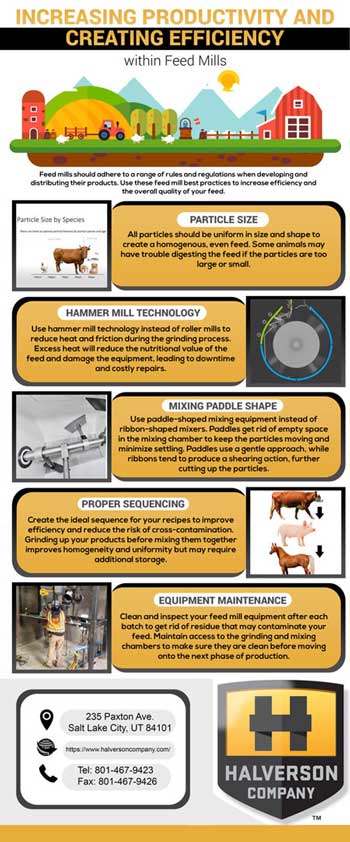

Increasing Productivity and Creating Efficiency within Feed Mills

Feed mills should adhere to a range of rules and regulations when developing and distributing their products. Use these feed mill best practices to increase efficiency and the overall quality of your feed. Particle Size All particles should be uniform in size and...

What Kind of Mixer Produces the Most Uniformed Feed?

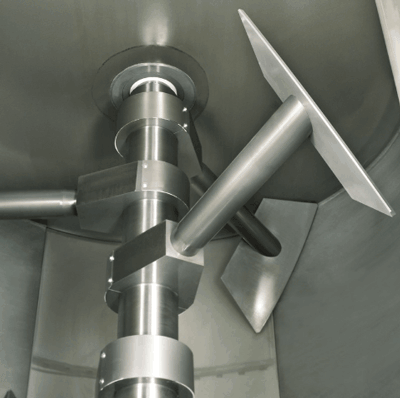

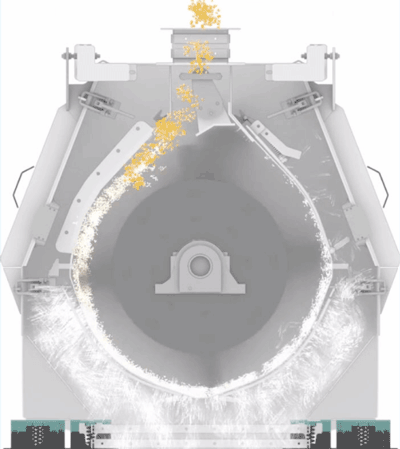

Mixing is at the heart of every feed mill facility. This is considered one of the most important, and sensitive, components of the feed milling process. The goal of the mixing process is to create a uniform feed for your animals and livestock. Generally, this means...

Feed Mill Best Practices

There are many things to consider when operating and configuring a feed mill. The goal is to get as much high-quality product out the door as efficiently and as cheaply as possible. Feed processing typically involves several steps, including sequencing, grinding,...

Ways to Reduce Mixing Time

Feed mill mixing tends to be one of the most expensive and time-consuming aspects of running a feed mill. Combining all your source ingredients into a consistent, nutritious product can be a challenge, especially if you’re using the wrong equipment. There are several...

How to Ensure Uniformity of the Feed is Achieved

Making sure the particles of your feed are uniform in size is crucial to the mixing process. If some of your particles are too large or too small, they will either sink or rise to the bottom of the batch, making it nearly impossible to create a consistent product for...

Feed Mixing & Particle Size

The size of your particles can have a major bearing on the overall accuracy of your animal feed. If your particles vary too much in size and shape, they won’t mix as evenly as larger particles sink to the bottom and larger particles rise to the top. This reduces the...

New Technology in Feed Mills

The feed mill industry is evolving quickly as businesses large and small look for better ways to develop and manufacture their products. Scientists continue to research the relationship between the mixing process and the overall health and safety of our nation’s...

Mixing Accuracy

Feed mixing is about making sure you have a nutritious, consistent product to feed your animals and livestock. If the feed is improperly mixed or not consistent from one batch to another, the health and well-being of your animals may suffer as a result. Several...

Liquid Addition to Feed Mix

In feed milling, there are generally two types of feed: dry feed and liquid feed. You may decide to add liquid to your dry feed before the mixing process or towards the end, depending on the nature of your feed and mixing equipment. However, if you add too much liquid...

Mixers: Paddle Vs. Ribbon

When running a feed mill, you have two options when it comes to choosing a mixer: paddle mixers and ribbon mixers. This speaks to the shape of the paddles used in the mixing process. Both styles can be effective, but they are designed for different applications and...

Feed Mixing Sequencing

When running a feed mill, you need to use caution when running certain ingredients and medications through your facility. Each product or recipe comes with its own medicinal properties. If you deviate from the recommended sequence, you could pass harmful ingredients...

What is Traceability and How Can It Be Avoided?

In the feed mill industry, traceability is the idea of recording and documenting all ingredients and drugs that are used in your animal feed. Maining quality feed mix for your animals involves tracing the drugs and ingredients that go into your animal feed will help...

Pre Grinding vs Post Grinding Systems

When producing feed for your animals, there are two ways to grind your ingredients to create the perfect feed mix quality: pre-grinding and post-grinding. Pre-grinding means grinding up individual ingredients before you mix them together. Post-grinding means grinding...

Mixing Quality

Animal feed mixing is the heart and soul of any feed mill operation. Most feeds contain a range of raw ingredients that vary in size, shape, and consistency. The facility will need to break up and thoroughly mix these ingredients together to create a homogenous random...

Why is Feed Mill Mixing Important?

When it comes to producing animal feed for your livestock, you need to thoroughly mix your raw ingredients together to produce a uniform product that will benefit the health of your animals. The mixer is often known as the heart of the feed mill. All raw materials...

Top Industrial Construction Companies: What You Should Know

Nothing could be more crucial to your business than starting a new construction project. If you want to save money and build a lasting addition to your business, you need to look for construction firms that share your vision. In today’s fast-paced industry, the top...

Grain Bin Safety Information

Grain storage tends to be the most dangerous potential hazard in the agricultural industry. Farmworkers can easily become entrapped in these bins when inspecting, breaking up, or unloading various agricultural products. The U.S. sees around 15 to 20 grain bin-related...

Planning a New Feed Mill

Like any major commercial undertaking, designing a new feed mill requires a great deal of forethought and an acute understanding of the current trends in your industry. To make the most of your new feed mill, you need to make sure the facility will help you reach your...

Hammer Mills vs. Roller Mills: What’s Better for Your Business

When supplying feed to your livestock, you’ll need to choose between two types of feed mills: hammer mills and roller mills. Both types of milling come with their fair share of pros and cons and making the right decision for your business all depends on the types of...

Feed Mill Design & Construction: Top Things to Consider

When building or designing a new feed mill, there are plenty of different factors to consider. No two facilities are exactly alike. You’ll need to adjust your plans based on the size of your facility, what you’re trying to achieve, and what kinds of animals you’re...

How to Improve Energy Efficiency in the Milling Process

Feed mills tend to produce thousands of pounds of animal feed every day, if not every hour. Powerful hammer and roller mills crush flour, wheat, and other grains to create animal feed, consuming large volumes of energy in the process. As the owner and operator of a...

Creating the Right Sized Particles for Your Animal Feed

Getting animal feed particles down to the right size is an important part of the feed milling industry. If your particles are too large, too small, or irregular in size and shape, your operations will suffer as a result. Different species of animals have different...

A Passion For Safety

Memories can change our lives. They can warm our hearts and teach us valuable lessons. In the case of Steve Halverson, one memory in particular, is helping him teach an important lesson to others about safety. When he was 18, he was spending the summer on the...

Contact Us

Let’s chat about your next project. A member of our expert sales staff can help answer your questions or even create a proposal.